The Benefits of Partnering With an Innovative Pipeline Manufacturer in 2023

In the ever-evolving landscape of pipeline facilities, straightening with an innovative manufacturer in 2023 can considerably boost functional capacities and reduce costs. By leveraging advanced innovations and personalized options, companies can not just enhance efficiency yet additionally ensure compliance with strict safety requirements. On top of that, the long life of materials and wise tracking systems can bring about considerable long-term cost savings. As sectors deal with increasing governing pressures and sustainability difficulties, the inquiry emerges: exactly how can critical partnerships truly drive makeover and cultivate an one-upmanship in such a vibrant environment?

Access to Advanced Technologies

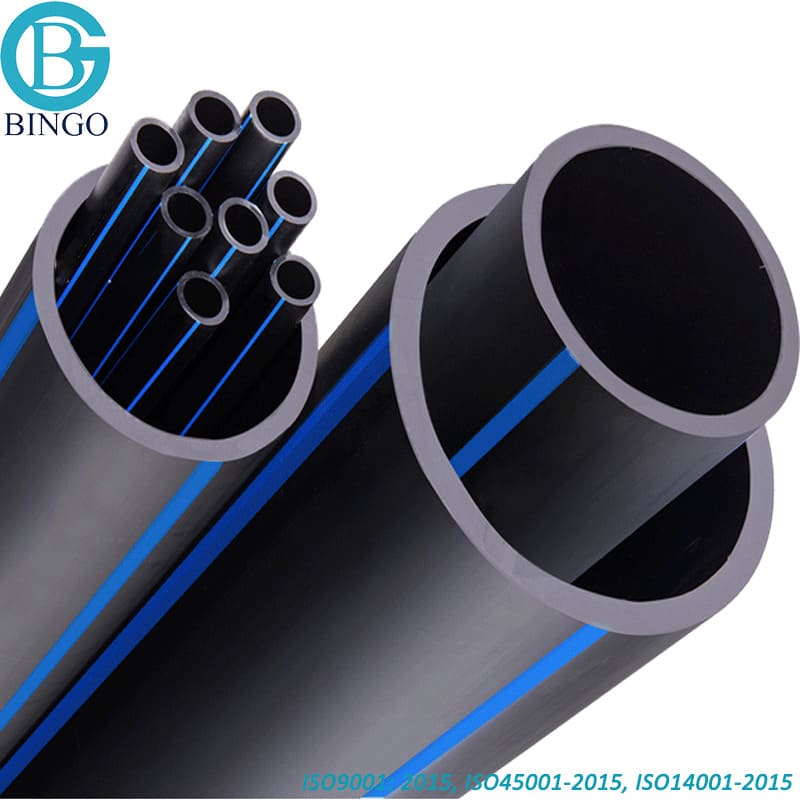

As sectors develop and the demand for performance and sustainability increases, partnering with a pipe manufacturer gives accessibility to advanced modern technologies that can substantially enhance operational performance (HDPE Pipe Supplier). These modern technologies include state-of-the-art products, ingenious design techniques, and cutting-edge production procedures that boost pipeline performance and longevity

One substantial advantage of teaming up with a respectable pipeline manufacturer is their investment in r & d. This commitment allows them to integrate the most up to date advancements in pipeline technology, such as clever sensors and automation systems, which facilitate real-time surveillance and upkeep. Such innovations not just improve safety however also lessen downtime, ultimately resulting in increased efficiency.

Additionally, producers frequently use innovative simulation and modeling tools to maximize pipeline design, making sure that systems are tailored to certain functional requirements and ecological problems. This degree of precision can lead to extra efficient transport of fluids and reduced functional prices.

Customized Pipeline Solutions

Personalized pipeline services provide customized layout alternatives that provide especially to the distinct requirements of each task. This approach not only enhances operational effectiveness yet additionally assures affordable options that straighten with budgetary constraints. By partnering with a pipeline manufacturer, services can accomplish peak efficiency and dependability in their pipeline systems.

Customized Layout Options

In the domain name of pipeline production, customized style alternatives supply substantial benefits that can boost functional effectiveness and satisfy details task needs. Customization allows producers to create pipelines that satisfy the distinct needs of numerous sectors, assuring peak efficiency across varied applications.

Among one of the most essential aspects of tailored design options is the ability to pick products and setups that align with the specific ecological problems and operational stress of a project. This guarantees resilience and longevity, reducing the threat of failures or pricey repair work. Additionally, innovative manufacturers use innovative innovations such as 3D modeling and simulation, enabling precise layout modifications and enhanced top quality control during the manufacturing procedure.

Tailored layouts also promote the combination of additional functions, such as specialized finishings or insulation, which can additionally boost the pipelines' functional capabilities. By working together very closely with clients, suppliers can identify the specific needs and restraints of each project, leading to remedies that not just satisfy regulative requirements yet likewise go beyond client assumptions.

Ultimately, partnering with a supplier that provides customized layout choices encourages companies to accomplish their task goals with self-confidence, guaranteeing that their pipeline systems are both reliable and reliable.

Enhanced Operational Effectiveness

Boosted operational effectiveness is a critical benefit of partnering with a pipe manufacturer that supplies tailored options. Customizing pipeline designs to satisfy certain functional demands makes it possible for services to optimize their procedures and enhance efficiency. Custom-made pipes can be crafted to suit unique pressures, flow rates, and environmental conditions, making certain that the system runs at peak efficiency.

By making use of innovative materials and technologies, innovative makers can develop pipes that reduce rubbing losses and decrease upkeep demands. This not just extends the life expectancy of the facilities however additionally leads to a more trusted and consistent flow of products. The assimilation of smart innovations, such as sensing units and automated tracking systems, better improves functional performance by giving real-time data on system efficiency.

In addition, personalized pipeline remedies promote far better combination with existing facilities, enabling smooth upgrades and growths as company demands advance. This versatility assists organizations react swiftly to market demands without giving up performance. On the whole, partnering with a manufacturer that specializes in personalized pipeline remedies equips business to attain functional quality, enhance operations, and maintain an affordable side in their industries.

Economical Solutions

Partnering with a pipeline manufacturer that provides tailored options not only improves operational effectiveness yet also results in considerable price financial savings. Personalized pipeline services are made to meet the details requirements of a project, making sure that resources are used successfully and lowering unnecessary expenses. By addressing special specifications, these options reduce product waste and optimize resource allotment.

Additionally, a dedicated collaboration cultivates collaboration, enabling producers to supply insights and referrals based upon market ideal techniques and emerging patterns. This positive strategy enables companies to remain ahead of potential challenges, better driving down expenses related to redesigns or delays.

Eventually, choosing a pipe manufacturer that prioritizes personalized solutions not just yields prompt financial advantages but additionally positions organizations for lasting success in a progressively competitive landscape. By purchasing customized pipeline services, firms can accomplish both functional excellence and significant cost performances.

Enhanced Functional Performance

Considerable renovations in operational effectiveness can be attained through cooperation with a specialized pipeline manufacturer. By leveraging sophisticated innovations and tailored designs, these producers simplify manufacturing processes and improve system efficiency. This collaboration permits the growth of pipes that are specifically customized to fulfill the distinct needs of different industries, making sure suitable circulation rates and marginal downtime.

Additionally, ingenious pipeline manufacturers use cutting edge products that not just boost durability but likewise lower upkeep requirements. This leads to fewer interruptions and an extra trusted pipeline system, eventually enhancing overall operational efficiency. Additionally, the integration of automated monitoring systems enables real-time information evaluation, assisting in positive decision-making.

Such proactive measures aid in recognizing prospective issues before they rise, enabling timely interventions that keep operations running efficiently. Training and assistance given by specific producers additionally empower in-house teams to operate and preserve these systems successfully.

Cost Decrease Techniques

Collaborating with a specific pipeline manufacturer not only improves operational performance however also results in reliable price reduction methods. By leveraging sophisticated production methods and cutting-edge materials, these manufacturers can give high-quality pipes that need much less frequent upkeep and replacement. This long life equates straight into cost financial savings over the task's lifecycle.

Additionally, a specialized manufacturer normally provides tailored solutions customized to particular operational demands. This personalization decreases waste and enhances source utilization, additionally driving down costs. Furthermore, the assimilation of innovative technologies, such as automation and wise surveillance systems, enhances precision and decreases labor expenses connected with pipeline installation and surveillance.

Partnerships with innovative pipeline makers can also bring about economic situations of range. By participating in mass buying or lasting agreements, companies can discuss far better rates and reduce overall expenditure - Permian Basin HDPE Pipe Supplier. Simplifying the supply chain with a committed manufacturer decreases delays and associated expenses, guaranteeing an extra efficient job timeline.

Sustainability and Environmental Effect

The expanding focus on sustainability in the pipeline market shows a wider dedication to ecological stewardship. As organizations progressively identify their duty in mitigating environment modification, ingenious pipeline makers go to the leading edge of creating sustainable solutions. By utilizing innovative materials and modern technologies, they develop pipes that not only boost performance yet likewise minimize ecological effect.

One considerable element of sustainability is the concentrate on lowering greenhouse gas exhausts during manufacturing and procedure. Suppliers are embracing methods that prioritize renewable resource sources, bring about lower carbon footprints. Moreover, the style of modern-day pipelines frequently incorporates attributes that assist in easier recycling and repurposing at the end of their lifecycle.

In addition, innovative manufacturers are welcoming water preservation techniques in their procedures, making sure that water usage is reduced and waste is effectively handled. These initiatives add to much healthier environments and demonstrate a commitment to accountable source administration.

In partnering with a forward-thinking pipeline manufacturer, firms can enhance their own sustainability efforts, aligning with governing demands and public assumptions. This collective method not just cultivates a positive corporate image but additionally plays a crucial duty in developing a sustainable future for the market.

Improved Security Standards

Partnering with a pipeline manufacturer significantly enhances security standards via using innovative materials and technologies - Texas Pipeline Manufacturer. Enhanced product resilience lowers the danger of leaks and failings, guaranteeing higher honesty of the pipeline systems. Furthermore, the incorporation of sophisticated safety technologies additionally reduces possible hazards, producing a more secure operational environment

Improved Product Durability

Improved product durability is an important variable in improving security standards within pipeline operations. The integrity of pipeline systems depends heavily on the products made use of in their building. Advanced products, such as high-performance alloys and composite materials, exhibit exceptional resistance to impact, exhaustion, and corrosion damage. This boosted resilience decreases the threat of pipeline failures, leakages, and succeeding ecological hazards.

Cutting-edge pipeline suppliers prioritize the option of products engineered to endure extreme problems, including temperature fluctuations and chemical exposure. By making use of these sophisticated materials, drivers can considerably prolong the lifespan of their pipeline systems, making certain reliable efficiency in time. This longevity not just minimizes maintenance costs however also boosts safety and security by lowering the regularity of inspections and fixings that can subject workers to prospective hazards.

In addition, enhanced product sturdiness contributes to regulatory conformity, as pipelines require to satisfy stringent safety and security standards. Manufacturers that invest in creating robust materials aid operators keep compliance, therefore preventing costly penalties and project hold-ups. To wrap up, partnering with a producer concentrated on enhanced material toughness straight associates to boosted safety criteria, fostering a much more secure functional setting for pipeline systems.

Advanced Safety And Security Technologies

Numerous advanced safety innovations are changing the pipeline industry, substantially improving security requirements and functional efficiency. As pipelines become increasingly crucial for delivering vital resources, the assimilation of ingenious modern technologies is necessary for alleviating threats and ensuring conformity with rigorous policies.

One remarkable innovation is the application of real-time surveillance systems that make use of Net of Points (IoT) gadgets. These systems continually track flow, stress, and temperature prices, offering drivers with immediate understandings to identify abnormalities that may show potential hazards. Moreover, automated shutoff valves are being released to immediately isolate areas of the pipeline in case of a leak or tear, significantly lowering ecological impact and guarding employees.

Furthermore, progressed data analytics and artificial intelligence algorithms are being used to forecast maintenance requirements, permitting proactive interventions prior to concerns escalate. American Plastics LLC HDPE Pipe Solutions. This anticipating method not just boosts safety and security however also decreases downtime and functional costs

Working together with an innovative pipeline manufacturer that prioritizes these innovative safety and security technologies will encourage firms to stay ahead of industry requirements, eventually bring about safer and more efficient operations. Embracing these advancements is important for promoting a culture of security and dependability go to this web-site in the pipeline field.

Lasting Strategic Collaborations

These collaborations offer a system for continuous renovation and adaptation to market needs. As innovations and regulations advance, a dedicated pipeline manufacturer can aid ensure that your procedures stay competitive and compliant. This flexibility is crucial in a quickly changing market landscape.

Long-lasting partnerships foster depend on and placement in goals, which promotes much better interaction and problem-solving. A shared vision permits both parties to prioritize sustainability and advancement, ensuring that both business can grow together.

Additionally, such collaborations typically result in special rates and boosted service terms, enhancing the general value of the partnership. Inevitably, purchasing a long-term strategic partnership with an innovative pipeline manufacturer not only bolsters functional capacities but also positions your business for sustained development and success in the pipeline sector.

Regularly Asked Inquiries

Just how Do I Pick the Right Pipeline Manufacturer for My Requirements?

What Industries Advantage Most From Cutting-edge Pipeline Solutions?

Innovative pipeline remedies considerably benefit markets such as oil and gas, water management, chemical handling, and renewable resource. These sectors need advanced innovation to improve efficiency, safety and security, and environmental sustainability while attending to evolving functional obstacles.

Are There Funding Options Available for Pipeline Projects?

Yes, numerous financing choices are readily available for pipeline projects, consisting of traditional financings, government gives, public-private collaborations, and job funding (HDPE Pipe Supplier). These choices can facilitate financial investment and support the advancement of vital facilities in the industry

Just How Can I Assess a Manufacturer's Online reputation and Integrity?

To analyze a maker's credibility and reliability, conduct comprehensive study by evaluating customer reviews, market qualifications, previous job portfolios, and seeking recommendations. In addition, evaluate their monetary stability and adherence to security and high quality requirements.

What Is the Common Timeline for Pipeline Job Completion?

The normal timeline for pipeline job conclusion differs significantly based upon job extent, regulative approvals, and environmental assessments, typically ranging from several months to a couple of years, relying on the intricacy and place of the job. Pipeline Manufacturer.

In the ever-evolving landscape of pipeline infrastructure, aligning with an innovative manufacturer in 2023 can considerably boost functional capacities and decrease expenses. As industries develop and the demand for efficiency and sustainability increases, partnering with a pipe manufacturer provides access to advanced modern technologies that can substantially boost functional performance. Improved functional performance is an essential advantage of partnering with a pipe manufacturer that offers customized remedies. Partnering with a pipe manufacturer significantly enhances safety requirements via the usage of advanced products and modern technologies. Establishing an enduring relationship with a credible pipeline manufacturer can enhance operational performance and drive development.